Hydroflux to Design, Build & Operate the Aquarevo WRP using Organica Process

November 19, 2024

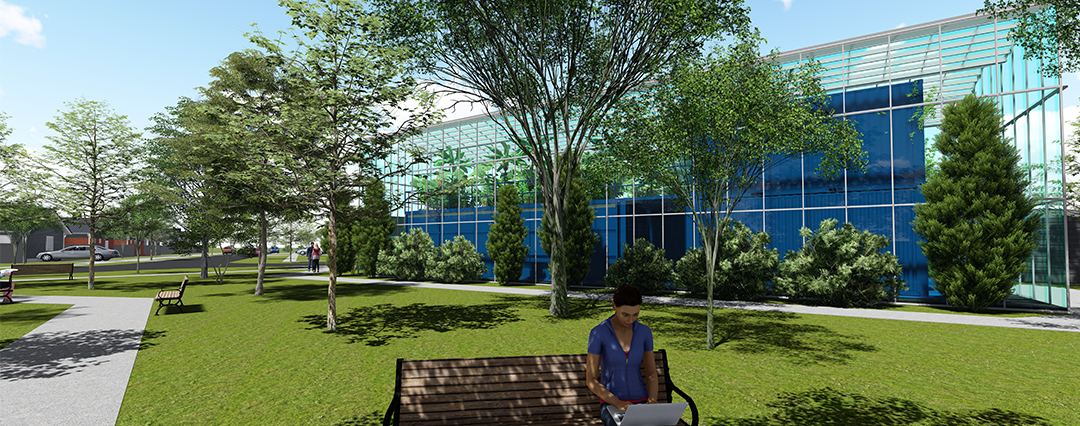

South East Water has awarded Hydroflux the Design, Build and Operate of the Aquarevo Water Recycling Plant (WRP) for the groundbreaking Aquarevo Development. The WRP will reduce reliance on potable water by approximately 52 Million litres per annum. An Australian first, the design of the Bluehouse™ will include an Organica Food Chain Reactor (FCR) that has been designed to make the treatment facility look like a natural garden that will seamlessly allow the facility to blend into the development.

Aquarevo is a collaboration between South East Water and Villawood Properties to create a water and energy efficient urban housing development in Lyndhurst. Each Aquarevo home will be plumbed to three sources of water (drinking, recycled and rainwater).

“What makes this recycled water plant unique is the utilisation of locally sourced plant species operating within a greenhouse and integrated as part of the Bluehouse™ treatment process. This provides a natural element to the recycled water process. Essentially this compact, energy efficient water-like garden will provide the community at Aquarevo high quality Class A recycled water, in a facility that resembles a botanical garden, blending into the surrounding green space.

Aquarevo is a blueprint for water-sensitive communities as it demonstrates the highly efficient use of water and energy in housing. Climate change, population growth and water scarcity will continue to challenge urban planning, so using all alternative water sources such as the new recycled water plant and other features of the Aquarevo homes, demonstrates what can be done to build resilience whilst enhancing liveability” says John Koumoukelis, CEO of Hydroflux.

The Organica process combines natural indigenous plants and engineered media, arranged in an activated sludge process as a fixed film bio-reactor, to provide a highly robust, low foot print and energy efficient treatment process.

The interaction of natural plants with the activated sludge promotes the growth of a dense bio-film, which diversifies the ecology within the reactor, providing a high level of robustness against process upsets, shockloads and storm events. Furthermore, emission of odour and noise is controlled and minimised.

To learn more, please contact Hydroflux on 773 6950 or visit www.hydrofluxepco.au.

About the Hydroflux Group

The Hydroflux Group aims to deliver the highest level of engineering and scientific know-how to the emerging issues of sustainability, climate adaptation and environmental protection with a specific focus on water and wastewater.

As part of its vision and mission, Hydroflux has always taken its climate responsibility seriously. In 2022, Hydroflux became Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for its organisation and products. It knows that partnering with customers and clients is the most significant impact it can have in its journey. The Group employs over 100 staff and operates throughout Australia, New Zealand and the Pacific Islands, with office locations in Sydney, Melbourne, Brisbane, Perth, Auckland, Suva and Portsmouth.

Up Next

Treating Metal Contaminated Wastewater Streams with HySEP®

Secondary Treatment Upgrades for Tākaka and Murchison WWTPs

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement