Mining

Hydroflux is a leading provider of tailored water treatment solutions. With extensive experience and expertise, we specialise in developing customised solutions that address the unique water treatment needs of each site and operation.

Our team understands the complexities of water treatment and the unique conditions faced in mining. No operations and processes are identical and as such, we believe in the importance of tailored solutions. We work closely with the with each operation to develop optimised treatment solutions uniquely designed to suit site conditions and operational needs.

We have designed water treatment solutions for various aspects of a mine’s operational requirements. This includes treatment of process water, potable water and wastewater treatment for onsite operation and mining camps. Our equipment and systems are built to be extremely robust with minimal maintenance to take into account the harsh environment and remoteness of many operations.

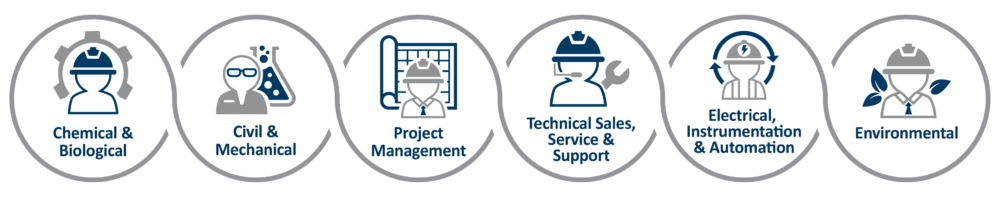

The Hydroflux team brings decades of experience in water treatment and a deep understanding of the requirements in the mining sector. Our team consists of dedicated project managers, process and mechanical engineers, electrical & automation and technical support engineers. This multidisciplinary approach enables us to offer end to end solution for your project and direct ongoing support with experts who are familiar with your project and requirements.

Find out more

Water plays a vital role in various processes, streams, and critical operations within each operation. The significance of water becomes even more pronounced considering the remote and harsh environmental conditions in which mine sites are often located, along with the challenges of water availability.

Hydroflux specialises in providing customised solutions to address all aspects of a mining operation, including:

- Process water treatment. Maximising recycle and treatment for application for dedicated systems which may otherwise require a cleaner water source (i.e. raw water, potable water)

- Raw water, bore water, potable water treatment plants. Removal of contaminants for dedicated process systems or critical operations (i.e. safety showers, washdown, facilities)

- Waste water treatment systems, for facilities and camps.

- Tailings management

- Environmental discharge & regulatory compliance

- Mine remediation

We understand that each operation is unique, in its process, operations, location and environmental requirements. We approach each project collaboratively with a tailored and engineered approach, utilising proven technologies to provide a solution that meets and exceeds performance requirements, whilst remaining cost effective and a focus on minimising maintenance and maximising availability.

Some of our technology scope includes:

Potable water is perhaps one of the most valued water on site. Potable water supplies operations with their drinking water, site amenities, safety equipment and specific process systems (i.e. safety showers, gland water, chemical batching). Hydroflux provides complete, onsite potable water treatment solutions customised to your water source.

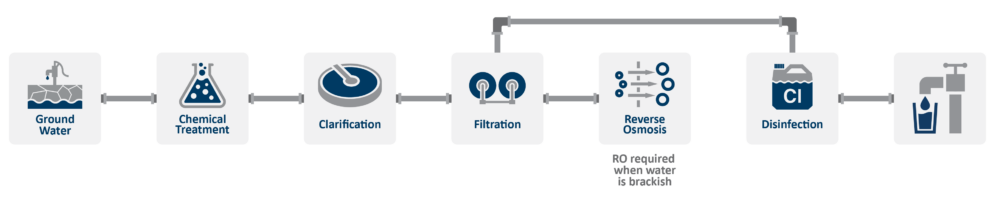

Groundwater is a common source for many potable water treatments that Hydroflux supplies. The quality of ground water can vary depending on the location and the geological characteristics of the surrounding soil and rock formations. In some areas, the groundwater may have a high level of salinity due to the presence of dissolved minerals and salts, making it brackish. A typical process which Hydroflux employs for treatment includes:

Depending on your water source:

- For high turbidity, the initial stage of treatment will usually involve chemical coagulation followed by clarification. This process aims to remove suspended solids and particles from the water, enhancing its clarity and reducing turbidity.

- For non-brackish water with low levels of dissolved salts, the secondary and final treatment approach involves media filtration followed by disinfection. Media filtration effectively removes impurities and particulate matter from the water, while disinfection destroys harmful microorganisms, ensuring the production of potable water.

- For brackish water, a popular method of treatment is the utilisation of reverse osmosis (RO). This involves passing the brackish water through a semi-permeable membrane to effectively remove dissolved solids and salts. Reverse osmosis is highly efficient, capable of removing up to 99% of salts and minerals present in brackish water. Hydroflux can also incorporate Ion Exchange technology for similar purposes, utilising a resin bed that facilitates the exchange of ions.

Hydroflux can provide your full potable water treatment solutions tailored to your operation requirements, containerised or skid mounted for easy installation and operations.

Most mines are situated in remote areas and to extreme conditions with sensitive environments and shared water resources. Wastewater treatment of onsite facilities and camps must incorporate water treatment solutions that are efficient and allow for ecological restoration and include monitoring. They must also consider fluctuations in water supply and varying contaminants. For many operations, treatment demands can include effluent to be reused in onsite amenities.

Hydroflux have been designing, developing and supplying wastewater treatment plants for over 60 years. Hydroflux’s RoadTrain activated sludge plant is one of the most robust and simple to operate wastewater treatment plants, designed specifically for remote operations and highly customisable to accommodate various needs, capacities, conditions and local water supply.

The original RoadTrain have been installed in the mining industry since the 1960s with upgraded versions still supplied and heavily favored among our clients today due to its customisation and scalability. RoadTrains were installed in the Bowen Basin coal mine, located in central Queensland in the 1970s designed to cater for 400 people. After a series of relocations and upgrades, it accommodates for up to 800 people in 2012.

Today, the RoadTrain range offers several options from activated sludge treat process to enhanced nutrient removal. Diagram and specifications of the original RoadTrain and its variations today can be found in the gallery below and through this link. The RoadTrain has also been engineered in pre-fabricated systems that can be simply bolted to a concrete slab. They arrive to site in a flat pack system reducing logistical issues for sites with minimal road access or absence of cranes. This was the case for a bolted RoadTrain that was installed at Moro village within the Oilsearch mining lease in the Papua New Guinea southern highlands in 2015.

Our team of experienced consultants from Cress Consulting, a division of The Hydroflux Group are committed to uncovering opportunities for sustainable growth.

These include:

|

Climate resilience:

We assess climate risks and determine climate adaptation responses to strengthen your resort’s resilience to a changing climate. |

|

Water stewardship:

We help resorts adopt effective water stewardship practices, identify risks and opportunities and support collaboration to address shared water challenges. |

|

Sustainability Strategy:

We work closely with resorts to assess current practices, identify opportunities to enhance sustainable tourism, design and implement a comprehensive sustainability strategy. |

|

ESG reporting:

Our team conducts a thorough assessment of your resort’s sustainability practices, identifying areas for improvement and developing an ESG strategy to maximise positive impact and enhance transparency. |

|

Carbon accounting and emissions reduction:

Our team helps resorts measure, manage, and reduce greenhouse gas emissions. We conduct carbon assessments, develop emission reduction plan, and support the implementation of a roadmap to enhance the transition to net zero. |

|

Training and Capacity Building:

We provide training programs to enhance staff knowledge on climate change, water stewardship and other sustainable practices as well as support effective implementation of strategies, plans and programs. |

Our expertise and comprehensive solutions will help you secure a resilient, sustainable future.

For more information, please visit cress.au

Hydroflux are specialists in both water treatment and wastewater treatment. We pride ourselves having dedicated inhouse teams across our offices, including:

Our inhouse capabilities uniquely position us to take your project from design right through to installation, commissioning, and provide continued technical support and chemical supply.

Each team and department is closely integrated, providing full understanding of design impacts on process efficiency, CAPEX and OPEX costs for each operation. Our familiarisation and experience with mine spec standards including safety, civil, mechanical, electrical, instrumentation and automation means we produce a compliant and optimsed design from the start of the project.

For each project, our experienced team also provides assistance with:

| Process Design, PFD & PID | All process equipment and component selection | Plant layout designs | Electrical design and automation | Project management |

| HAZOP reviews & workshops | Installation (mechanical & electrical) | Civil & building works and designs | Commissioning & site supervision | Technical workshops, virtual and onsite training |

| On going technical support | Chemical, consumables & spares supply & support | Quality assurance plans | Environmental / OHS plans and reports | Documentation for compliance or regulatory bodies |

Hydroflux specialises in integrating our high standards for system design and safety with site-specific engineering requirements, prioritising our customers’ requirements above all else. This commitment ensures that each project achieves the best possible outcome.

Hydroflux Utilities is a division of Hydroflux that provides comprehensive ongoing support and service network for all Hydroflux customers and projects throughout Australia.

Our team consists of multidisciplinary engineers and technicians who are experts on the equipment and systems and provide hand on support. This is an essential aspect to our support team, as this experience and familiarisation provides unparalleled support for our customers. This directly translates to minimal downtime for your plant and tailored optimisation solutions.

Hydroflux provides ongoing support and services to hundreds of water treatment plants across Australia.

We are able to cater for any water treatment requirements and tailer a program to meet your project requirements.

Click below for more information on we can support and optmise your operations.

Chemical Supply & Optimisation | Preventative Maintenance & Service | Modelling, Optimisation, Audits & Testwork | Rental Equipment | Remote Monitoring & Support

Chemical Supply & Optimisation

Hydroflux has a comprehensive range of coagulant and flocculants suitable for conditioning water, wastewater or sludge. The most appropriate chemical program will be determined before commissioning based on experience, or test work if possible, and long-term cost-effective chemical supply contracts can be arranged.

Click here for more information on our chemical supply.

Preventative Maintenance & Service

Our engineers and technicians will discuss service and maintenance programs with you during construction of the treatment plant so that you can be assured that the system will perform consistently from day one.

Our engineers and technicians will discuss service and maintenance programs with you during construction of the treatment plant so that you can be assured that the system will perform consistently from day one.

There are many types of programs available from routine preventative maintenance, periodic service and overhauls, to complete plant operation. Our team can provide virtual or onsite training on all aspects and available 24/7 to attend to unforeseen breakdowns.

Click here for more information on our maintenance and service programs

Modelling, Optimisation, Audits & Testwork

Optimisation often represents the single biggest opportunity for performance improvement and reducing operating costs. Our team can conduct performance audits, develop and implement optimisation strategies to improve the efficient of your operations.

Optimisation often represents the single biggest opportunity for performance improvement and reducing operating costs. Our team can conduct performance audits, develop and implement optimisation strategies to improve the efficient of your operations.

New project? Or expansion? Let our experienced engineering team assist with modelling of your processes. We also have capabilities to conduct lab based or onsite testwork and sampling to ensure the best solution provided for your project.

Click here for more information on our optimisation services

Rental Equipment

Hydroflux has a fleet of water treatment solutions for pilot and rental. This is ideal should you require a quick and temporary solution, or looking to trial a new equipment/process.

Hydroflux has a fleet of water treatment solutions for pilot and rental. This is ideal should you require a quick and temporary solution, or looking to trial a new equipment/process.

Our rental fleet includes (but not limited to): Lamella clarifiers, Sludge dewatering systems, Surface diffuser cleaning systems, Mobile auto-samplers, Chemical dosing systems and more

Click here for more information on rental equipment

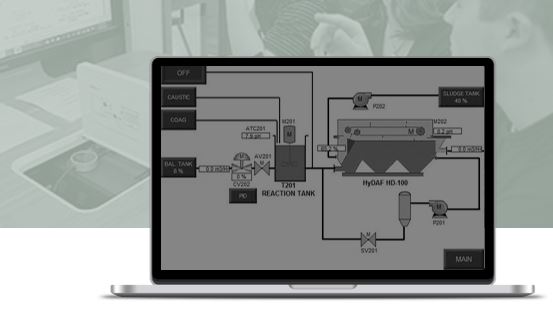

Remote Monitoring & Support (HyConnect)

HyCONNECT® is a remote connection facility utilised by the Hydroflux Group to provide advanced support to our clients. This facility provides our experienced wastewater technicians and engineers 24/7 real time access to our client’s treatment plant control system to assist with any support required.

HyCONNECT® is a remote connection facility utilised by the Hydroflux Group to provide advanced support to our clients. This facility provides our experienced wastewater technicians and engineers 24/7 real time access to our client’s treatment plant control system to assist with any support required.

The features of the HyCONNECT® system include a Secure Remote Login to HMI screens or SCADA for complete operation and monitoring.

The HyCONNECT® system utilises an Ethernet Modem Router utilising a secure VPN. The system requires a valid signal (enhanced antennas available) and access through client’s firewall if installed.

HyCONNECT® is available for all treatment plants and processes and included by default with many of our packages.